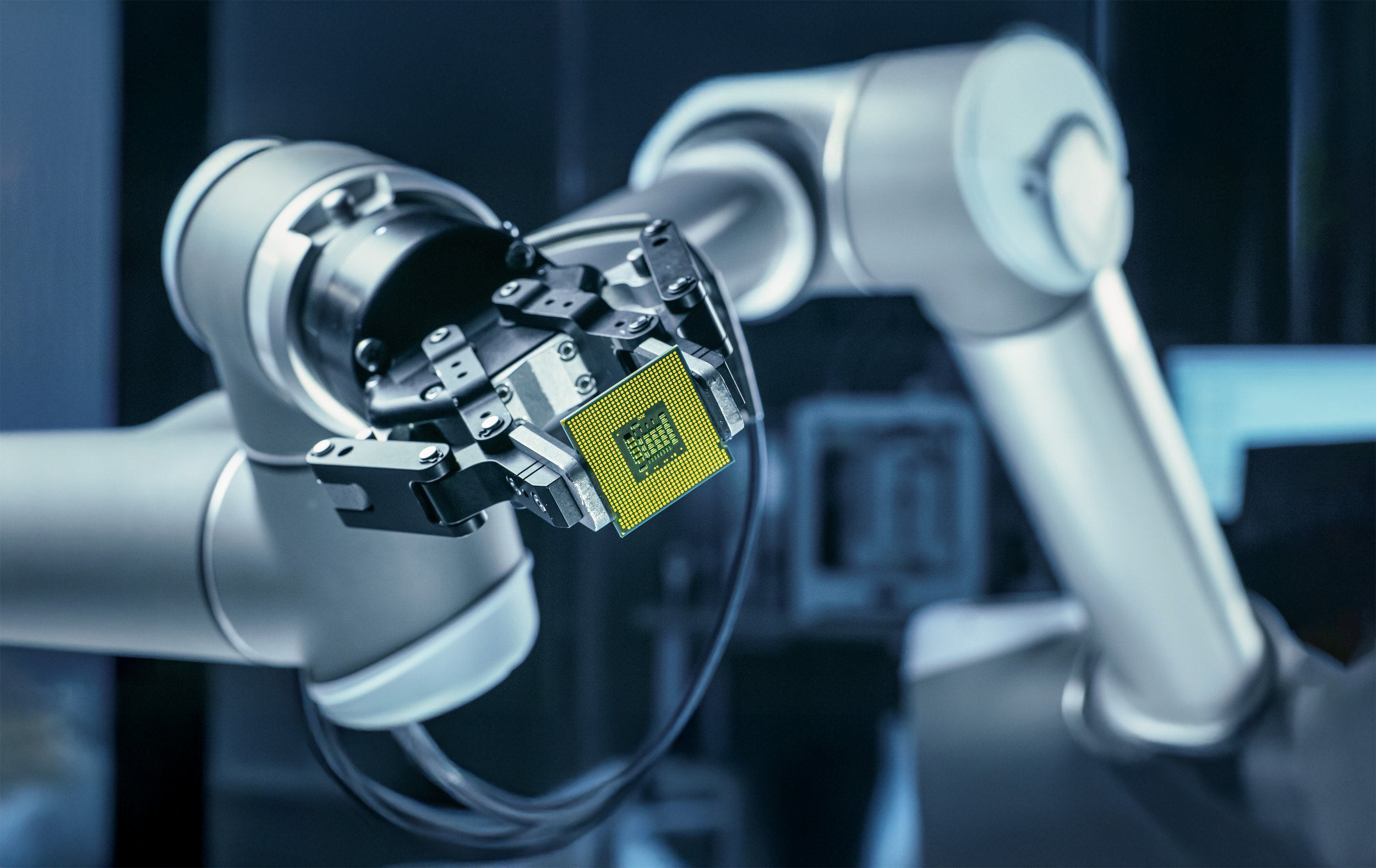

Revolutionizing Manufacturing

with Automated Microfactories.

At Aspired, we are pioneering the future of manufacturing by developing automated microfactories that transform how products are made – on-demand, in smaller batches, and closer to the consumer - while harnessing the power of automation, robotics, and cloud-edge computing to optimize every step of the process.

Here's how implementing microfactories can transform your operations:

Cost Reduction

Microfactories can reduce manufacturing costs significantly due to their smaller scale, lower energy consumption, and reduced labor requirements. High levels of automation and AI technology enable more efficient operations and the ability to implement changes without significantly increasing costs. Some microfactories use up to 90% less water, up to 50% fewer chemicals, and up to 80% less energy than traditional factories (World Economic Forum, 2024), contributing to cost reductions.

Productivity Increase

The integration of AI and automation into microfactories can boost productivity by 15-30% (World Economic Forum, 2024). The modular design of microfactories allows for simultaneous execution of multiple tasks, which accelerates production cycles and reduces idle time. This flexibility leads to faster, more efficient manufacturing processes. Additionally, cloud-edge computing solutions can reduce system downtime by 35% (Tekvaly, 2024), further enhancing overall productivity.

Energy Savings

Microfactories typically consume 20-80% less energy (World Economic Forum, 2024) compared to conventional manufacturing plants. This is primarily due to their smaller physical footprint and the use of energy-efficient technologies, such as optimized lighting, automated machinery, and advanced cooling systems. AI-driven HVAC (heating, ventilation, and air conditioning) systems can further reduce energy costs by 20-73% (Applied Thermal Engineering, 2023), optimizing climate control and energy usage.

Reduced Carbon Footprint

By localizing production and reducing the need for long-distance transportation, microfactories can lower their carbon footprint by up to 67% (Gelato, 2024). This is a crucial benefit for companies aiming to improve sustainability and reduce their environmental impact. The ability to produce goods closer to the end consumer not only cuts down on transportation emissions but also decreases packaging waste. Decentralized manufacturing can also reduce transport and logistics costs by 18% while enabling a 22% faster order fulfillment time (Robert Ziner MBA, 2024).

Faster Time-to-Market

The microfactory model enables companies to shorten their time-to-market by up to 22% (Robert Ziner MBA, 2024). This speed advantage is achieved by providing rapid reconfigurations of production lines, allowing manufacturers to quickly adapt to changing market demands or customer preferences. Cloud-edge computing solutions further enhance this efficiency by reducing latency by up to 90% (The Quantum Zeitgeist, 2024), ensuring real-time decision-making and seamless production adjustments.

Enhanced System Reliability

The implementation of cloud edge computing can reduce system downtime in the event of network outages by 35% and reduce latency to less than 5 milliseconds, compared to 20-40 milliseconds for cloud-based computing (Tekvaly, 2024). This ensures higher operational efficiency and resilience in automated production environments.

Why Choose Microfactories for Your Business?

By integrating automation, robotics, and energy-efficient technologies, the microfactory systems provide faster, smarter, and more cost-effective ways to produce high-quality products. As industries continue to evolve, the future of manufacturing lies in smaller, more agile, and sustainable production methods - and microfactories are leading the charge.

Let’s work together

Reach out to us to explore how we can work together to create microfactories tailored to your specific needs and business goals.

Aspired SIA

Toms Vācietis

+371 29 476 782

toms.vacietis@aspired.lv

Nextgen Microfactories

January 1, 2025, to December 31, 2027

Project "Nextgen Microfactories" focuses on developing smart, highly automated microfactories by integrating cloud-edge computing and AI-driven robotics. The project aims to improve manufacturing efficiency and sustainability, reducing reliance on non-European cloud service providers.

By developing and testing cloud-edge solutions for mobile robotics, industrial automation, and decentralized production, the project contributes to the transition towards Industry 5.0. These innovations will help optimize production processes, reduce operational costs, and support the development of energy-efficient manufacturing ecosystems.

Our partners